Using Paper Or Metal In A Roof Valley

Installed correctly it provides a unique aesthetic especially when using painted or copper coil stock.

Using paper or metal in a roof valley. How to measure and cut the metal on a valley for metal roof install. Open valleys on the other hand leave the metal exposed which may be more pleasing to the eye especially if copper is used as the valley lining. Use fasteners to attach the panel to the structure making sure that there is complete compression of the sealant. And if problems with roof leaks or other damage occur years later an open valley system is.

How to seal metal roof valley. That flashing is left exposed so the roof has visible lines of metal running down the valley. The metal valley is installed on top of the ice and water shield and creates a highly effective barrier and passageway to keep your roof dry and protected. Some homeowners do not like the look of open valleys while others feel the metal accentuates the roof s shape particularly if copper or painted flashing is used.

Failure to extend the entire width of the metal valley flashing beyond the eave of the roof. This will reduce the installed cost of the project. How to install roofing paper in a valley section and install the valley flashing on top. With a clean valley you can lay down some peel and stick roofing membrane.

A metal valley is a pre bent roofing material designed to protect these vulnerable areas on your roof. Best practices for sealing the metal roof valley vary based on the slope of the roof. While there are a number of materials that can be used. Why is a metal valley important.

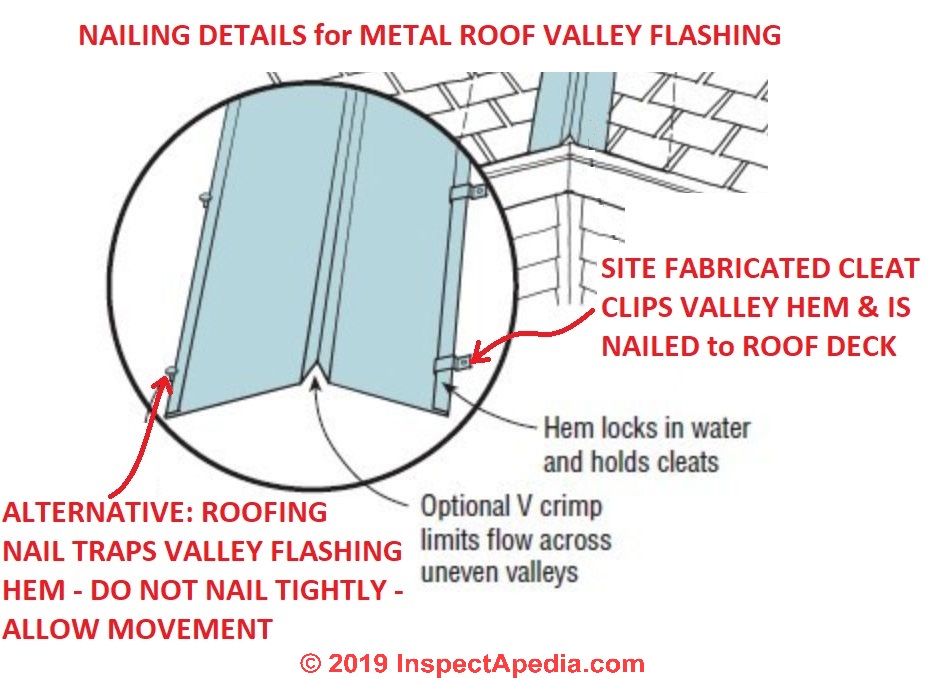

Punctures in the center of the valley. Fasteners placed in the exposed center area. He notes that due to the metal construction of an open valley it may shed ice and water more quickly which could help minimize granule loss. Roof mastic applied along sides of valley flashing.

Closed cut valley fully replaced with new metal valley flashing. An open valley relies on metal flashing for protection. Low slope roofs slope less than 3 12 use tape sealant between the valley trim and the panel. This video shows the water proofing paper that we installed after re.

Provided the rest of the roofing shingles were properly installed and are performing properly my experience has been that an open valley system holds up better over time says jeff tessaro of iko roofing company. Contractors may be able to reduce the cost of materials on roofing projects by eliminating the metal being installed in the valleys. Install synthetic roofing underlayment or felt paper according to manufacturer specifications and then install the first piece of valley flashing. Still using metal for roof valleys has proven to be a popular choice among roofing experts.