Using A Torch To Solder Copper Gutters

You have to use a soldering iron only not a torch.

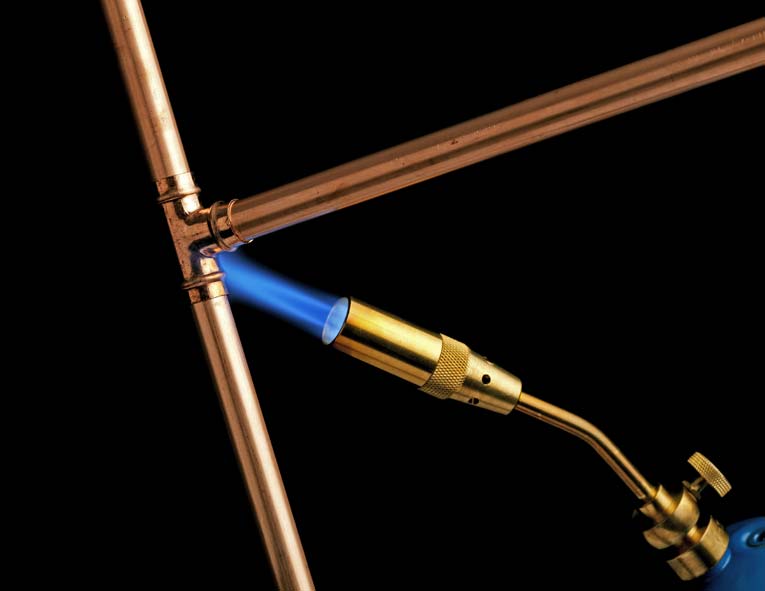

Using a torch to solder copper gutters. How to solder copper gutters. Hold the flame on the tip of pipe to heat. Let us check out the top five in the market. The flux will turn to liquid and the pipe will change color slightly.

If the flame is orange turn gas down. Step 1 get the right equipment. Step 3 observe complete caution. I ve had a older fella explain and show me where the iron hasmore benfits than the mapp torch tinning and also lacing built in gutter on the joints for more integrity.

Follow me on instagram franklincustomcopperworks norwalk ct 203 9978069. That was a great week i learned shrinking strecthing the idea of roll stock is alot more difficult to work with than sheet stock where ruby flux is better than plumbers flux. When the pipe is heated touch the soldering wire to the joint. Seamless gutter subcontractor installs new copper gutters and they look great.

This precisely engineered torch for soldering copper pipes from big short is a highly reliable one. Marking the whole process rudimentary. While wearing safety glasses fire up the propane torch. Many companies make these torches for melting and soldering copper pipes.

Yo there dont use a torch on the gutters at all. All three parts of the flame should be blue. If you decide to solder your copper gutters yourself make sure that you bring the right equipment on site. Step 2 clean the surface to be soldered.

Richard trethewey shows another effective way to connect these pipes without pulling out the blow torch. It is a portable anti flare butane soldering torch which is loaded with a lot of useful features like the strong brass frame nozzle instant piezo crystal ignition a detachable base and precise flame control. How to connect copper pipes without soldering the tried and true method for connecting copper pipes has always been soldering but it s a difficult skill to master. Blazer gt8000 big shot butane torch.

Everybody is happy until a year later when all of the joint start to leak. Step 4 stay alert. Contractor or homeowner hires a sub with soldering experience to peel out the failing caulk grind the patina from the joints we will go over this process later flux and finally solder.