Use V Groove Router Bit To Cut Acrylic Sheet

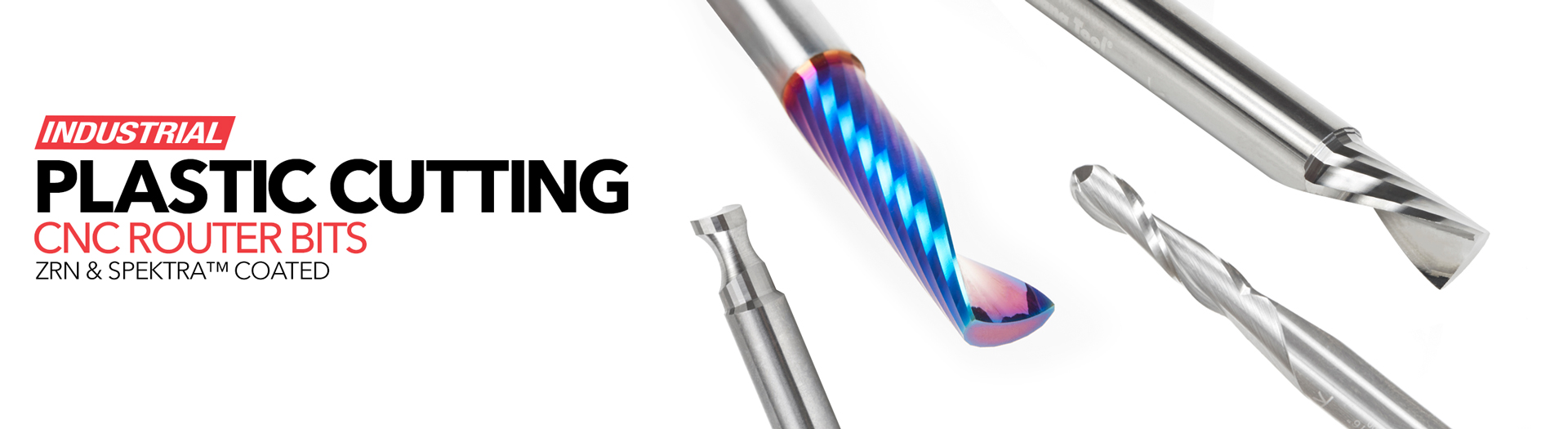

1 16 of over 1 000 results for plastic cutting router bit freud 73 206 1 4 inch diameter by 3 4 inch height o flute up spiral plastic cutting router bit with 1 4 inch shank.

Use v groove router bit to cut acrylic sheet. 90 degree v grooves are cut almost all the way through a rectangular sheet of acrylic one groove parallel to and equidistant from each side. All bits have a pilot to guide cuts. Because of its thermal stability flame polishing is a bit challenging with this acrylic. The pilot location is reversed when using the bit with a router table.

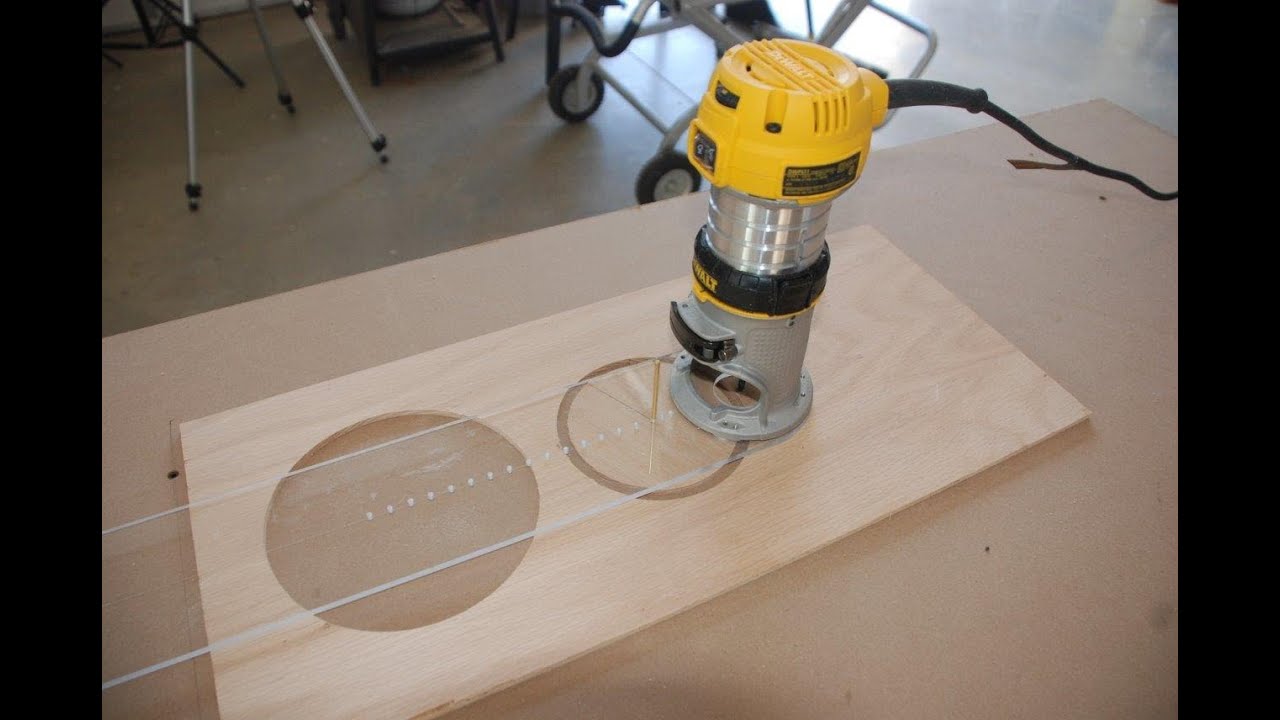

Use with an edge guide to chamfer and bevel edges. Free shipping by amazon. If you don t have one of several types of power saws available to use if you have a router it is possible to cut plexiglass with it provided you have the correct blade designed to make a flush cut a variable speed router when done right will cut plexiglass the heat generated by both power saws and router bits is enough to melt some of the plastic polymer material that comprises plexiglass. Strips of solvent proof tape are applied to the ungrooved side of the plastic one strip centered over and all the way along each groove.

Tipped v groove router bits cut decorative v grooves and lettering on signs with these v groove bits. Can be used with handheld table mounted and cnc routers excellent for cutting acrylic composites composite decking foam laminate melamine 37 75. Single and double fluted bits are commonly used. Save more with subscribe save.

Pilot location describes the position of the pilot when the bit is used for hand routing. Router bits for machining acrylic may consist of one to three flutes. Our customers typically get the best results using o flute end mill bits. 4 8 out of 5 stars 16.

The polishing tool path needs. They can be one piece multiple part bearing guided straight cutting forming or specialty bits. Router bits may be made of high speed steel hss carbide tipped solid carbide or diamond tipped. Bottom pilot bits trim material from an upper layer of the workpiece so that it is flush with the layer below.

Get it as soon as tue sep 8. The best method is to use a polishing bit to finish the job at the router. The plastic is bent and snapped at each groove. While you can use bits of all sizes it s generally advisable to use the largest bit possible for your design as this increases depth possible stability and removal of waste material.