Tpo Roofing Which Side Goes Out

Short for thermoplastic polyolefin tpo is a single ply roofing membrane that offers excellent performance at a cost effective price.

Tpo roofing which side goes out. Tpo roofing comes in 6 to 8 foot sheets that you lay out side by side and weld together. Edge sealant is required at any cut edges splices and non encapsulated edge. Here at west roofing systems we ve been installing single ply membrane roofing for over 38 years. What goes into tpo roofing systems.

Roofers generally use one of two methods to adhere a tpo membrane to a roof. He felt that the friction caused by the rough side attached to the studs would help shear value he would do this with the osb tread material too. The rough side is made for safer walking. Heat welded seams provide superior strength.

To finally settle the score between epdm vs tpo a side by side comparison will help property owners make the right decision for their properties. 60 mil 1 5 mm thick reinforced tpo thermoplastic polyolefin membrane with weldable selvage edges of 2 75 69 9 mm on each side of the roll one encapsulated edge and self adhering capabilities in a wide temperate range. This will be expensive but i think is well worth it. For more information regarding tpo roofing systems contact the professionals at reliable roofing.

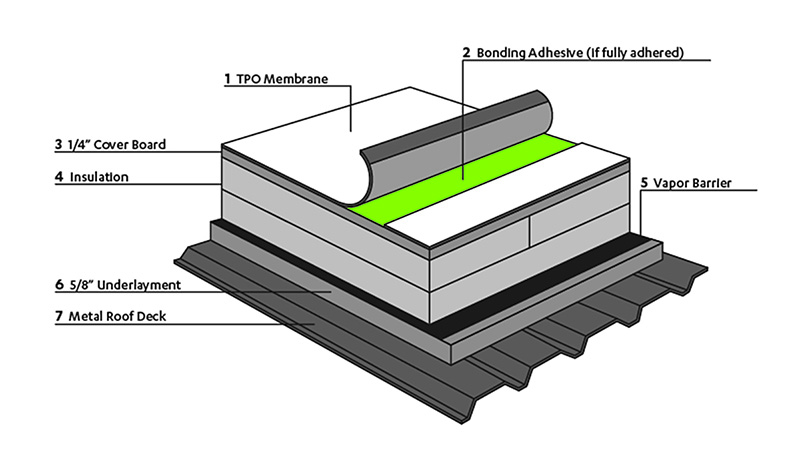

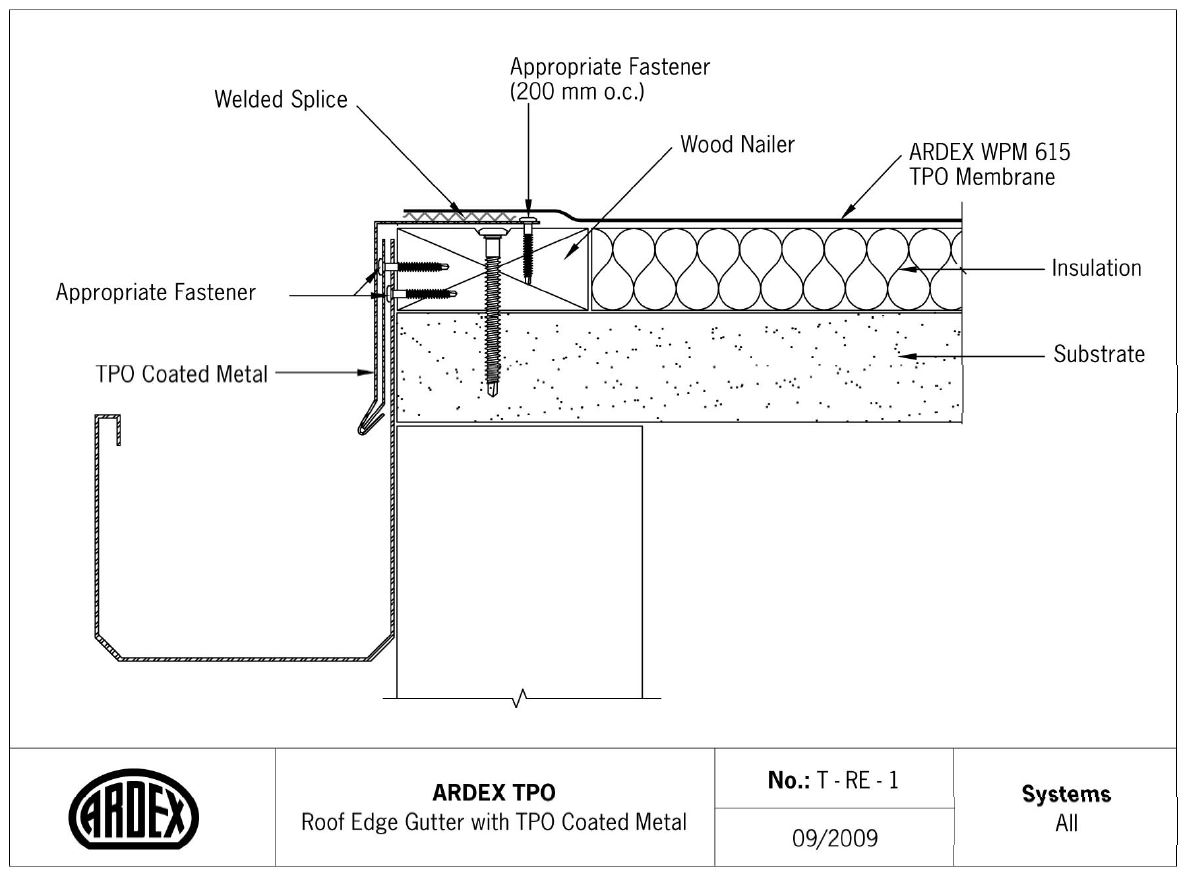

The tpo system consists of the membrane a cover board and or insulation tpo accessories tpo compatible metal and tpo compatible adhesive or fasteners. In this article we cover everything you need to know about tpo roofing. Epdm roof manufacturers combine recycled rubber material from old tires boots and other sources to create the material. Thermoplastic polyolefin tpo single ply roofing membranes are among the fastest growing commercial roofing products and have gained broad industry acceptance for their many performance and installation advantages.

The tpo roof system can be mechanically attached ballasted or fully adhered. As one of the most common roof types of big commercial facilities tpo has some of the best energy savings for single ply membrane roofing. The tremco thermoplastic polyolefin tpo roof system is a thermoplastic high reflective light weight energy star and california title 24 compliant roof system. This hand book should be used as a reference to.

Tpo s long term heat uv and natural fungal resistance plus flexibility without need for plasticizers also make tpo a reliable low slope roofing system. Also since most heat goes out through your roof i d recommend 3 inches of polyiso insulation on your roof. If you ve seen a bright white roof then you may be familiar with tpo roofing. Then they mix slate and sawdust to add density and strength.

One is to use mechanical fasteners which are typically screws accompanied by large plastic washers. Its been awhile but that was one of the benefits to osb that was listed on one of the manufacturer s websites.