Tpo Plastic Data Sheet

Download 1420g tpo data sheet.

Tpo plastic data sheet. Safety data sheet sds sds 115 thermo plastic olefin hoehn plastics inc. These products withstand whatever the elements and heavy use throw at them. The unusually outstanding thermoforming performance of our tpo sheet is just the beginning of the benefits for customers designing outdoor equipment and vehicles. Download 1410m tpo data sheet.

Primex also produces a line of printable grades of polyethylene for use in real estate signs and truck mud flaps. Duraflex 6500 is an engineered polyolefin used primarily as a high gloss cap layer for sheet extrusion and thermoforming of aesthetic articles. In our most recent post in the learn more about your plastic sheet blog series we featured our extruded hips material and highlighted some of the characteristics and attributes of the material. The uv grades of rtp company s tpo compounds were designed to be compatible with common paint systems to provide an all in one solution for situations where some parts are painted and some are not.

Poseyville in page 1 of 3 section 1. The result is a sheet that has the proper sag during the thermoforming operation assuring even material distribution and wall thickness. 585 546 6200 toll free. Premier material concepts data sheets.

High breaking strength tearing strength and puncture resistance is achieved by. Product and company information hoehn plastics inc 11481 west county road 925 south poseyville in 47633 812 874 2612. Download all of our tpo data sheets here. Not sure which grade of tpo is right for you.

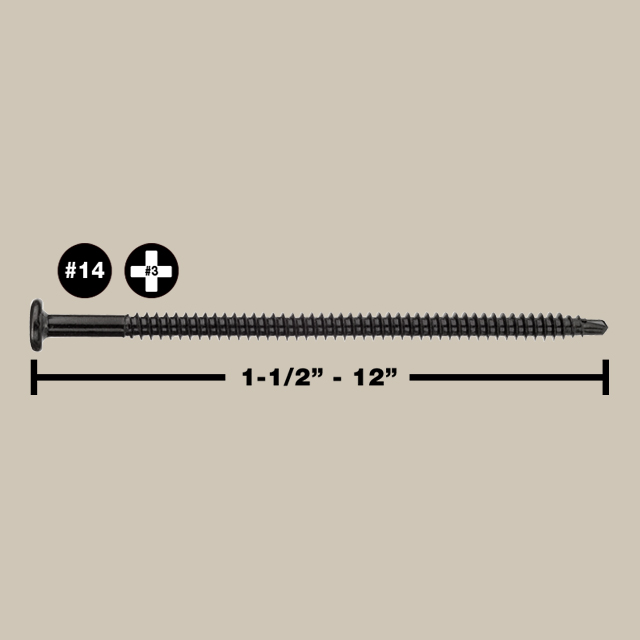

Tpo compounds can be formulated for increased uv weathering and scratch mar resistance when needed. Today we will switch gears to a polymer that services a more industrial market where material durability for long term use is paramount tpo or thermoplastic olefin. Product data sheet tpo c membrane standard fr and clean film product description revision date. Mar 2020 mule hide tpo c membrane is a polyester reinforced 045 or 060 thick polyolefin based thermoplastic heat weldable membrane.

The correct resin selection is essential to provide sheet that will perform properly. Ready to move forward. This material is supplied in natural uv stabilized and can be colored using typical tpo and pp color.